Search

-

Mühendi̇sli̇k Çeli̇kleri̇

- Rulman çelikleri

- Semantasyon çelikleri

- Isıl işlem ve çökelme sertleşmesine uygun çelikler

-

Korozyona Dayanikli Ve Demanyeti̇ze Çeli̇kler

- Ferritik ve martensitik çelikler, çökelme sertleşebilen çelikler

- Ostenitli çelikler

- Dubleks ve süper dubleks paslanmaz çelikler

-

HAVACILIK

- Türbin ve Motor Parçaları (Havacılık ve Uzay)

- Yapısal Elemanlar (Havacılık ve Uzay)

- Diğer Havacılık ve Uzay Parçaları

-

Plasti̇k Kalip Çeli̇kleri̇

- Plastik Ekstrüzyon

- Enjeksiyon Kalıplama

- Vidalar ve Kovanlar

- Gıda İşleme ve Hayvan Yemi Endüstrileri için Parçalar

- Takım Tutucular (frezeleme, delme, tornalama ve aynalar)

- All applications

-

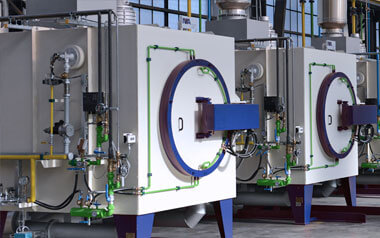

Enerji̇ Üreti̇mi̇

- Türbinler ve Kompresörler için Kanatlar ve Miller

- Endüstriyel Gaz Kompresörleri için Parçalar

- Buhar Vanaları

- All applications